It's estimated that about 500,000 detectable earthquakes occur each year throughout the world. While we typically associate earthquakes with structural damage, such as cracks, shifting and collapse, the impact to nonstructural building contents, systems, and structures can be just as devastating.

One of the most important nonstructural elements that can be damaged in an earthquake are automatic sprinkler systems. Unbraced or inadequately braced sprinkler systems can be damaged by even modest earthquakes when pipes, fittings, and sprinklers are exposed to seismic forces and contact walls, beams, ceilings and other building features.

Seismic sway bracing (Fig. 1) is used to minimize the differential movement between the sprinkler system piping and the building. Properly installed sway bracing makes it possible for the building and the sprinkler system to move as a single unit during an earthquake thereby limiting damage.

CE marking now possible for sway bracing

Until very recently, there were no CE marked seismic sway bracing systems available in the European Union. That's because, until now there were no harmonized European Norm (hEN) standards or European Assessment Documents (EADs) that covered this important category of fire protection products.

FM Approvals and its European Notified Body, FM Approvals Limited, have worked for almost two years to champion the adoption by the European Organization for Technical Assessment (EOTA) of EAD 16-10-0005-11.06, Rigid Seismic Sway Brace Components for Fire Sprinkler System Pipework.

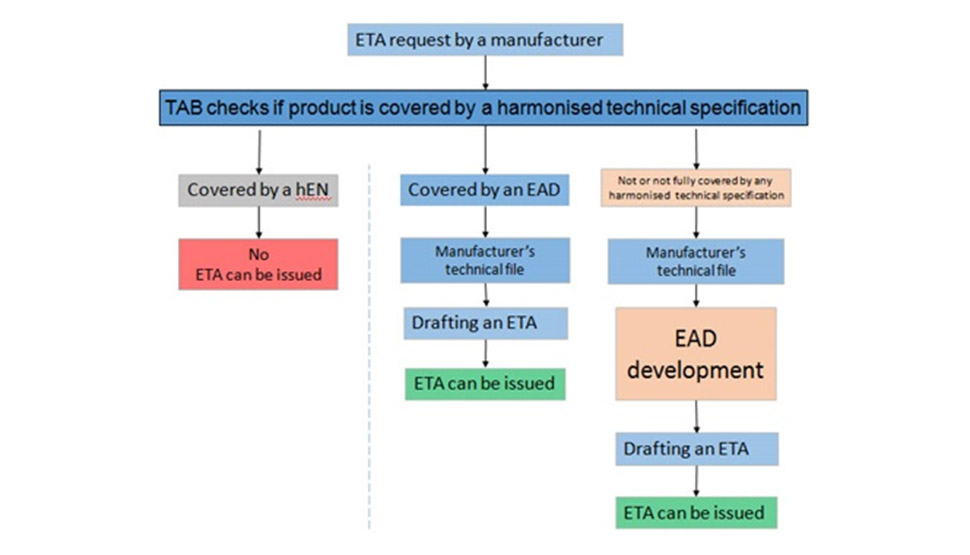

ANSI/FM Approvals 1950-2016, American National Standard for Seismic Sway Braces for Pipe, Tubing and Conduit, was the basis for the new EAD, which can now be used by any Technical Assessment Body (TAB) with the appropriate scope to issue a European Technical Assessments (ETAs) for seismic sway bracing products, which are covered by the Construction Products Regulation (CPR).

"The development of new European Norm standards can be a slow process," notes Dave Fuller, manager of FM Approvals fire protection group. "By utilizing the EOTA process, we developed the EAD and ultimately, the ETA, much faster. In the case of seismic sway bracing, we received a request from a long-time FM Approvals customer to help them develop technical specifications that could be used as the basis for CE marking for the EU market."

"Based on our track record, an EAD takes from 12 to 24 months to develop from the initial inquiry to issuing a European Technical Assessment," Fuller notes. "We start from the point where there are no harmonized standards available to initiating the process with EOTA, writing the standard, working with the manufacturer, producing and filing paperwork, and issuing the ETA (Fig. 2)."

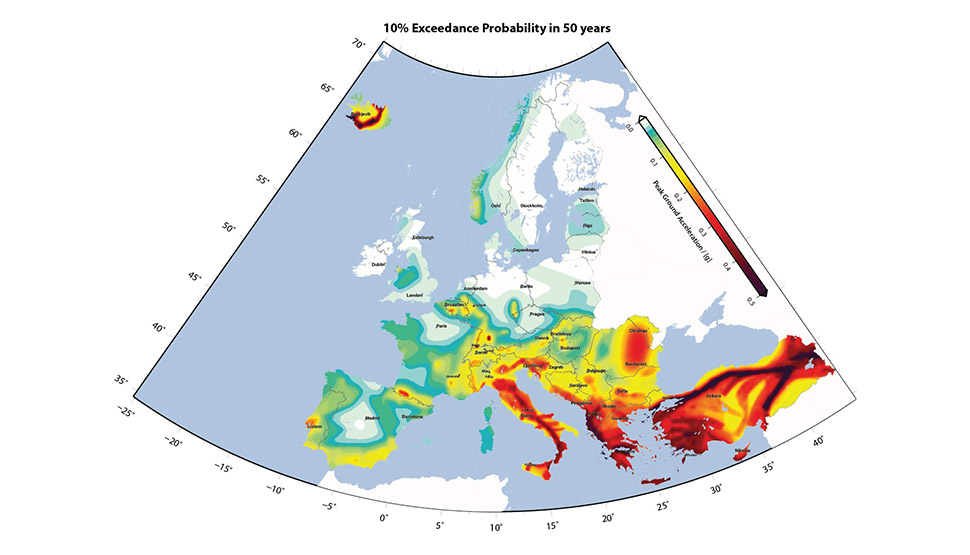

According to reports from the Seismic Hazard Harmonization in Europe (SHARE) project, which ended in 2013, the southeastern areas of Europe, including Italy, the Balkans, Greece, Bulgaria, Romania and Turkey (Fig. 3) are among the most at-risk regions of the continent for earthquake hazards.

"The Italian office of our customer really helped drive this effort," Fuller says. "With any effort to develop a European Assessment Document, a request is needed from a manufacturer who has a product that is not covered by an existing harmonized EN standard. This customer already had several FM Approved seismic brace products and they requested us to develop an EAD."

According to Fuller, FM Approvals history of developing EADs has been highly successful so far. The EAD for seismic bracing will be the third EAD produced by FM Approvals in the past few years, which also includes EADs for Early Suppression Fast Response (ESFR) sprinklers and flood protection products.

Fuller adds, "Seismic sway bracing is an important fire protection product and by enabling manufacturers—both current customers and those coming to us for the first time—to combine the FM Approvals certification with a CE marking program, we can help them save time and money and expand the acceptance of their products in more areas of the world."