Approval Standard 1616, Underground Pipe Rehabilitation Systems, which will be released by the end of the year, is intended to provide FM Approved systems for the repair and restoration of underground fire service water mains (fire mains). This critical element in supplying water to fire protection systems is often located in areas where it would be expensive and disruptive to completely replace. Yet, many fire mains were installed decades ago and have deteriorated to the point that they are leaking or at risk of failure.

For instance, on the evening of July 1, 2009, a 52-year-old cast iron fire main serving the westbound side of the Hampton Roads Bridge Tunnel ruptured. The break went undetected for more than eight hours. During this time, more than two million gallons of water flooded the tunnel, even though fire pumps were automatically switched on to feed the broken 8-inch (203 mm) fire main. It took another eight hours to pump out the tunnel and weeks to repair the ruptured fire main. The tunnel closure caused massive traffic delays and economic hardship over the July Fourth holiday (Fig. 1).

In October 2016, a break in a 14-inch fire main flooded Wallace Hall on the campus of Virginia Tech. The water destroyed the building’s 480-volt main electrical panel, several chilled water pumps, an air compressor, an electrical transformer and a chiller control panel. While the fire main was repaired in about three days, the floodwaters caused about five days of downtime for part of the building, which houses classrooms and administrative offices.

Leaking money

According to a recent study by Deloitte, there are approximately 240,000 water main breaks across the U.S. each year, with a direct cost of about US$2.6 billion. In addition, the cumulative cost to business between 2013 and 2020 due to degrading water/wastewater infrastructure is estimated to be US$147 billion.

The 2019 State of the Water Industry Report by the American Water Works Association (AWWA) found that the most critical issue among water professionals was "renewal and replacement of aging water and wastewater infrastructure." The No. 2 issue was "financing for capital improvements."

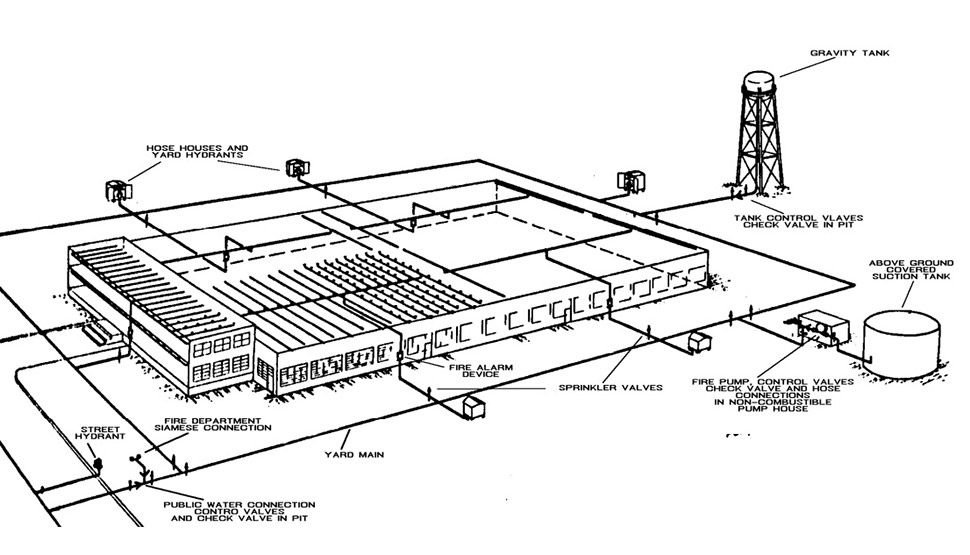

Most large businesses, educational institutions, medical centers, high-rise apartments and public facilities have a dedicated fire protection system that includes large fire mains often up to 12 inches (300 mm) or more. (Fig. 2).

While many private fire mains in use around the world are in need of repair or replacement, the disruption and high cost of replacement means this important maintenance is often postponed. Of course, the failure of a fire main during a fire can be catastrophic and the cost to repair a fire main on an emergency basis due to a break or leakage can be extremely high.

Sorting out the choices

"There are many types of pipeline relining and rehabilitation systems on the market," notes Dave Fuller, FM Approvals vice president and manager of fire protection. "There's no single magic solution that will reline all your pipes. However, we believe there are relining systems out there that could offer an effective and reliable solution to deteriorated fire protection water mains that avoids costly replacement. Our new standard will help differentiate the best solutions."

Pipe relining systems offer 'trenchless' rehabilitation for many types of pipe applications, including sewer, drinking water, and fire mains. With minimal digging required, these systems typically insert a resin-saturated liner made of fiberglass or polyester material into existing pipe that has been previously inspected and cleaned.

The liner is cured inside the pipe and junctions and connections are cut out of the new liner. The benefits of this type of system are many, including limited disruption, usually lower cost than full replacement, safety and fast recovery.

In fire mains, this type of rehabilitation system can dramatically reduce the downtime for fire protection systems. Certain systems, such as those using fiberglass reinforced felt, are designed for use in high pressure applications, such as sewer force mains, water lines, and even fire mains.

FM Approvals has a long history in the evaluation and certification of underground fire service piping. FM Approvals Standards for fire service pipe include:

- 1610 – Ductile Iron Pipe and Fittings

- 1612 – Polyvinyl Chloride (PVC) Pipe and Fittings

- 1613 – Polyethylene (PE) Pipe and Fittings

- 1614 – Fiber Reinforced Composite (FRC) Pipe and Fittings

New Approval Standard

Approval Standard 1616, to be released soon, encompasses the manufacture, quality control, installation and performance requirements of pipe rehabilitation systems. For instance, performance requirements covered in the standard include:

- Hydrostatic strength of both structural and semi-structural pipe rehabilitation systems. Structural pipe rehabilitation systems allow direct connection and tapping, and do not rely on the host pipe for performance. Semi-structural systems do not allow direct connection or tapping, and rely on the host pipe for full structural integrity.

- Vacuum test. Semi-structural pipe rehabilitation systems will be subjected to a vacuum test to ensure that they remain securely bonded to the host pipe.

- High flow endurance test. A cured sample will be subjected to a flow rate of 30 ft/sec (9 m/sec) and will show no signs of separation from the host pipe or any other failure, such as blistering, peeling, flaking or delamination.

"We know that there are a lot of fire mains in the world that have been compromised by corrosion and operational stresses," notes Stan Ziobro, FM Approvals assistant vice president and technical team manager and author of new FM Approvals standard. "These systems are vital for the proper performance of fire protection systems. The stakes are high. We believe there are pipe rehabilitation systems out there that can meet our standards. We are looking forward to working with manufacturers to achieve Approval and help provide reliable pipe rehabilitation systems for anyone who needs them."